Installation of Fiber Optics

An optical fiber is a thin, long, transparent material (usually made of glass or plastic) that confines and propagates light waves. Fiber optics use light pulses to transmit information down fiber lines. At one end of the system is a transmitter. This is the place of origin for information coming on to fiber optic lines. The transmitter accepts coded electronic pulse information coming from copper wire.

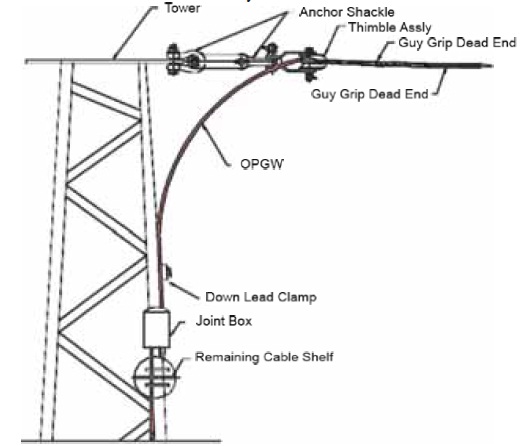

Fittings for Optical Fiber Ground Wire (OPGW)

An OPGW cable contains a tubular structure with one or more optical fibers in it, surrounded by layers of steel and aluminum wire. The OPGW cable is run between the tops of high-voltage electricity pylons. The optical fibers within the cable can be used for high-speed transmission of data, either for the electrical utility’s own purposes of protection and control of the transmission line, for the utility’s own voice and data communication. It is not advisable to use standard suspension and dead-end fittings as they apply radial forces that are in-admissibly high for the conductor. For this reason, spiral fittings or specially adapted end clamps are used.

Fiber Optics Installation Technique(ADSS)

Electrical

- Space Potential Effect

- Corona Effect Dry

- Band Arching

Mechanical

- Span Lengths and Sag

- Tension on Cable

Environmental

- Wind Velocity and Aeolian Vibration

- Sheath Composition for UV Resistance

- Temperature and Pollution Level

Fiber Optics Installation on transmission line structure at a distance of 3-6 meter Dry Band Arcingbelow the high voltage line is a general practice, which is considered to be a major cost saving installation process. Due to this relative geometric position of the cable and high voltage line, there is a capacitive coupling between the HV line (which is at phase potential)&fiber optic cable (Which is an earth potential due to

rod assemblies with

Services offered

- OPGW, ADSS & UG OFC Installation

- OFC Structure Network Design & Data Canter Implementation

- OFC Jointing & Commissioning with OTDR & OPTICAL Power Unit

- Electrical Conductor Installation & Commissioning

- Project Management Consultancy

- GIS Survey with PDA, DGPS & GPS:-1) Electrical Entity Survey 2) Door to door Survey

- GIS Mapping with Arc GIS Software:- 1) Rectification of Base Map and satellite imagery 2) Digitization of electrical network with electrical entities 3) Physical Map Creation 4) Indexing & Codification of Electrical assets